Wayne Tedder, the shipwright at Seaview Boat Yard, crouched under Petrel, jabbing a rigging knife into the garboard seam. He dug out a wad of rotten, wet, fibrous material - remnants of cotton caulking - and stood up. No explanation was needed. The old caulking had failed and the seams would need to be reefed out and recaulked.

A traditional wooden boat is like a barrel. The hull is made up of individual planks, carefully spiled - shaped to form a fair curve - laid edge to edge, and fastened to the frames that give the boat its shape and structure. The seams between the planks are then made watertight by caulking them with cotton or oakum (tarred jute), which is tapped into place using a caulking iron and mallet, and then “payed”, or coated with pitch or some similar substance to keep the caulking in place. When the boat is launched the wood swells, the seams close up, and the water is held at bay, for a time at least.

The garboard seam, where the bottom hull plank meets the keel, is called the devil seam by old sailors, and those who fancy themselves that way, thus the saying “the devil to pay and no pitch hot” - a phrase that was appropriate to our current situation. Done well, by a skilled shipwright, the caulking process creates a sound hull that will stay dry for decades but the caulking in Petrel’s garboard seams had deteriorated and was no longer keeping the water out.

After a disastrous three-day cruise to Gig Harbor, during which the sea, or at least that portion of the sea which had formed Puget Sound, refused to stay politely on the outside of the boat, we hauled Petrel out of the water to find and stop the leaks. And leaks were easy to find, as the water on the inside was now running back out of the bilge through the garboard seams, and puddling on the ground under the keel.

Repairs were needed, so over the next three weeks local shipwright and caulker Mark Lerdahl refastened the garboard planks, recaulked the seams, replaced two rotten planks on the port side, sistered several frames, and made other repairs to make Petrel watertight again.

After a quick coat of paint on the new planks, Petrel was launched on a gray September afternoon, with no more water coming in than we would expect from an extended stay in the boatyard. She was still half-finished, with empty rectangles where her pilothouse windows should have been, a makeshift aft deck, and nothing more than temporary cots for sleeping arrangements, but she was floating. We motored into the canal leading to the Ballard Locks, and home to her slip on Salmon Bay.

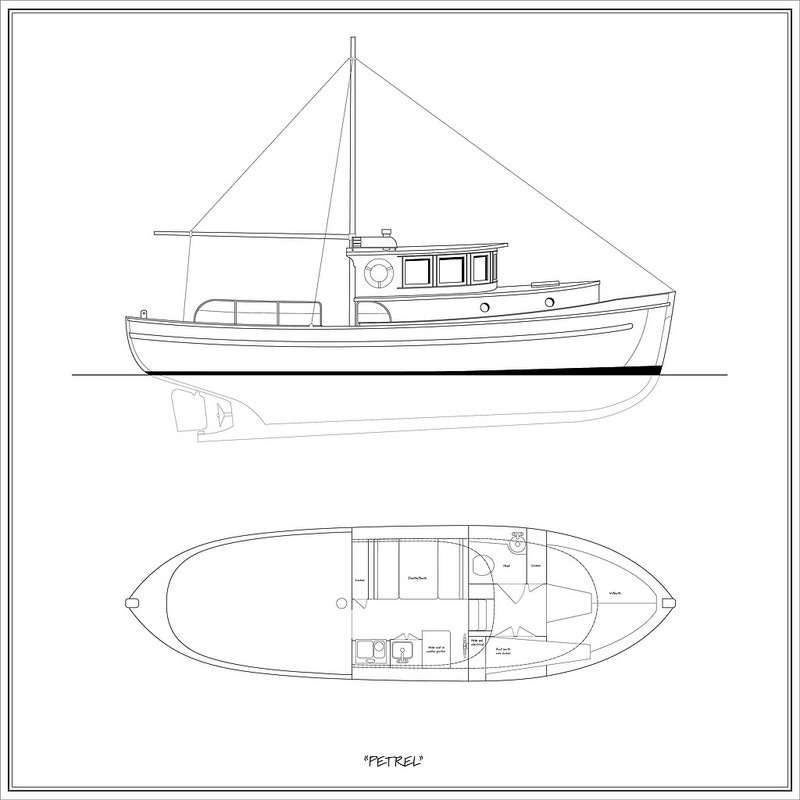

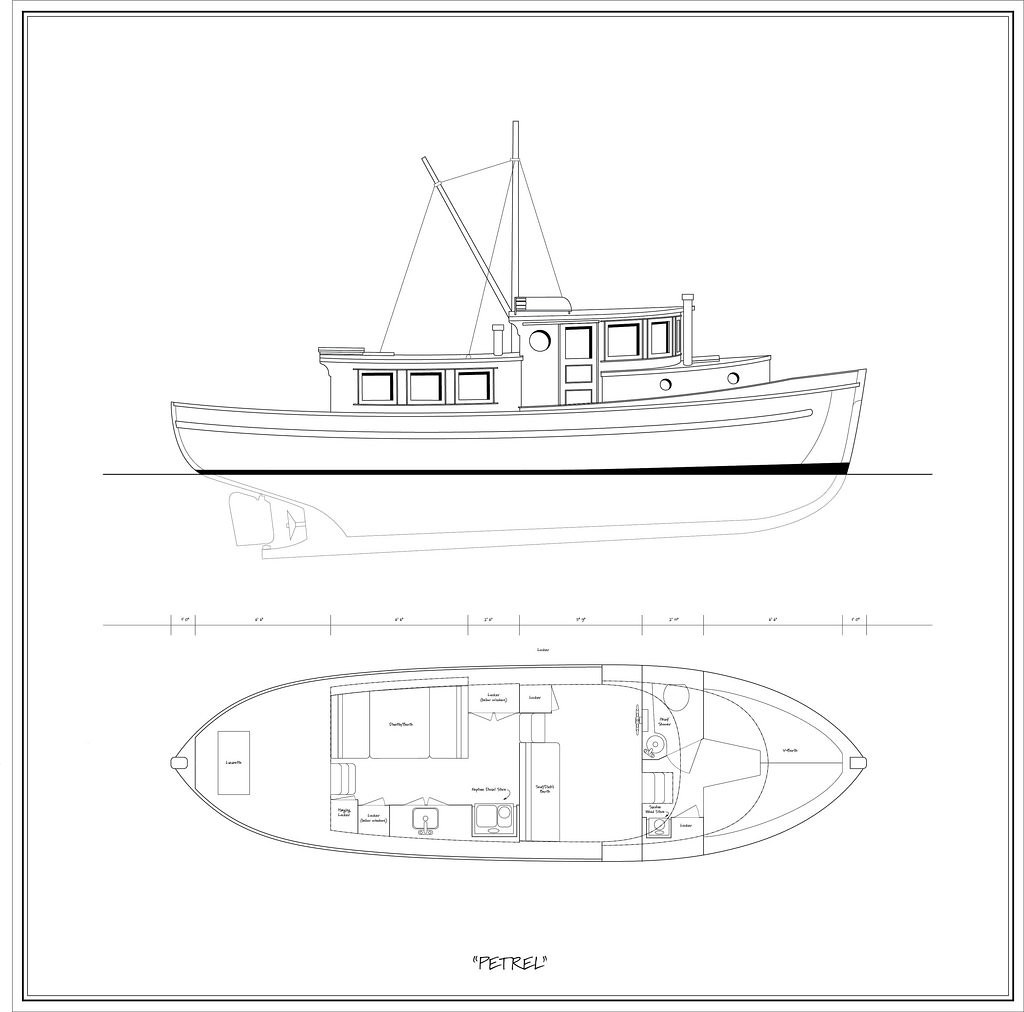

Petrel was watertight again, but she was still not a suitable boat for a family. She was too loud, too small, too open, and too unfinished. But she was what we had, so we dreamed about ways to turn her into a better family boat. Keeping with her original design, we could enlarge the pilothouse and add minimal accommodations, resulting in a simple, handsome cruiser with a galley, dinette, an enclosed head and berths for three, with room for a dog to curl up on the cabin sole (or wedge herself into the v-berth, as our dogs have always been inclined to do).

Or with more time and effort, we could build a full aft cabin, and have a comfortable all-season boat, with a wood stove in the fo’c’sle, a dedicated pilothouse, and enough room for everyone to stretch out with a book, or a puzzle, or to sit and watch the water.

These design exercises were aided by a group of online friends who contributed advice, ideas, and critiques, making for an enjoyable project through the fall and early winter, while Petrel sat at her mooring waiting for us to decide what to do next. But lines on paper were only the first step in a long effort to fit Petrel out as a cruising boat. It would take years of work or thousands of dollars to complete the project. And we wanted to go cruising right then, not in a few years.

At this point a deus ex machina entered stage left. Or, more prosaically, through the WoodenBoat Forum private message system, as Paul K., the owner of Skookum Maru, reached out to ask whether we would be interested in buying her. Skookum Maru is a classic cruising yacht designed by Ed Monk Sr., who was one of the most prolific and notable yacht designers of the twentieth century.

Ed Monk designs can still be found in any anchorage from Puget Sound to Alaska. They are all wonderful boats, but Skookum Maru is superlative - a handsome and well-appointed cruiser in the style of a Pacific Northwest workboat, with a deep, beamy, full displacement hull, a high, well-flared bow, a traditional curved pilothouse with good visibility all around, generous working area on deck, and a dry stack exhaust for the diesel engine.

As an enthusiast of Ed Monk’s designs I was somewhat familiar with her already so my first reaction was “wow!” and then “there is no chance that we could afford her.” But Paul said we should go see her and then talk about it. So we did. And that is the start of another story.

Skookum Maru is a beautiful boat and an appropriate happy ending to your story, but there is something perfect about Petrel. I hope she stays afloat. BTW, that seam called "devil" may not be the garboard but the one closest the waterline, i.e., "the deep blue sea." Check this explanation by someone who seems to know what he's talking about - the third answer down. https://www.quora.com/What-is-the-devil-seam-on-a-ship